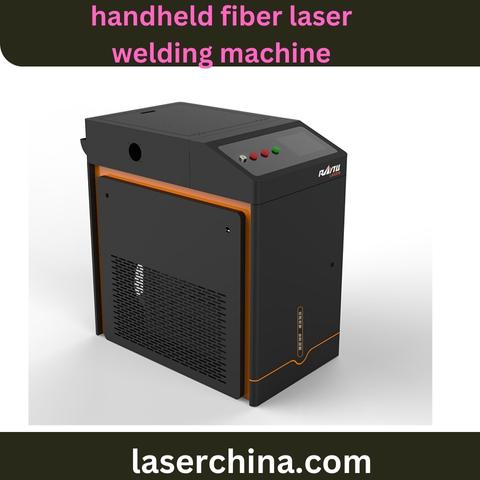

Handheld Fiber Laser Welding Machine: Precision Welding Anywhere for Industrial and Professional Use

The handheld fiber laser welding machine has become an essential tool in modern manufacturing and metalworking industries. With its portability, precision, and versatility, it allows professionals to perform welding tasks with unmatched accuracy and efficiency. Unlike stationary systems, a handheld fiber laser welding machine gives operators the freedom to work directly on parts without moving them to specialized workstations, streamlining processes and increasing productivity.

One of the key aspects that define the handheld fiber laser welding machine is its ability to produce consistent, high-quality welds on a wide range of metals. This includes stainless steel, aluminum, copper, and other alloys. Its focused laser beam penetrates metals with precision, enabling strong, clean joints. The handheld design ensures that even complex or hard-to-reach areas can be welded effectively, making it suitable for repair work, small batch production, and custom metal fabrication.

In addition to its precision, the handheld fiber laser welding machine is designed for operational flexibility. Operators can adjust welding parameters such as speed, power, and pulse frequency to match the specific needs of the project. This adaptability allows for a wide range of applications, from fine jewelry and electronics components to automotive parts and industrial machinery. Every weld is controlled, reducing material distortion and ensuring a smooth finish.

Maintenance and ease of use are critical aspects of the handheld fiber laser welding machine. The device is built to provide reliable operation over long periods, and its lightweight design reduces operator fatigue during prolonged use. Many modern machines come with intuitive controls and interfaces, making them accessible to professionals with varying levels of experience. This user-friendly approach ensures that operators can focus on the quality of their work rather than spending time troubleshooting equipment.

The versatility of the handheld fiber laser welding machine extends to its use in repair and maintenance tasks. For example, damaged components in industrial machinery can be restored quickly without the need for disassembly or replacement. In artistic metalwork, precise welding enables the creation of intricate designs and fine detailing. In the automotive sector, repairs and custom modifications can be performed directly on vehicles, saving time and resources.

Safety considerations are also an integral part of operating a handheld fiber laser welding machine. Proper handling, protective eyewear, and awareness of surroundings are essential to ensure a safe working environment. The precision of the laser minimizes the risk of excessive heat affecting surrounding areas, which is particularly important when working on sensitive or delicate materials.

Handheld fiber laser welding machines continue to evolve with technological advancements. Newer models are incorporating features such as integrated cooling systems, improved beam stability, and advanced control panels to enhance the overall welding experience. These improvements allow operators to achieve superior results with greater efficiency and accuracy, meeting the demands of modern industrial and professional applications.

The applications of a handheld fiber laser welding machine span multiple industries. In electronics, it enables precise joining of components without damaging surrounding circuitry. In aerospace, it provides strong, lightweight welds necessary for critical structural components. In jewelry making, the machine delivers fine, controlled welds suitable for delicate designs. Its flexibility and precision make it an invaluable tool across fields where quality and accuracy are paramount.

Portability remains a defining feature of the handheld fiber laser welding machine. Unlike traditional welding equipment, operators can move freely around the workspace, reaching tight spots and performing on-site repairs. This mobility reduces downtime and increases operational efficiency. For industries that rely on quick turnarounds and high-quality results, the handheld fiber laser welding machine represents a practical and effective solution.

The future of handheld fiber laser welding machines points toward even more compact, energy-efficient designs with enhanced control systems. As manufacturers continue to innovate, the capabilities of these machines are expanding, allowing users to undertake increasingly complex welding tasks with confidence. Professional workshops, repair facilities, and manufacturing units are all benefiting from the integration of this technology into their operations.

In summary, the handheld fiber laser welding machine is a remarkable tool for precise, versatile, and reliable metal joining. Its ability to deliver consistent results across a variety of applications, combined with its portability and user-friendly design, makes it indispensable in modern industrial and professional settings. Whether for repair work, custom fabrication, or detailed craftsmanship, this machine provides unmatched performance, enabling operators to achieve high-quality welds efficiently.

From intricate metal jewelry to large-scale industrial repairs, the handheld fiber laser welding machine continues to redefine what is possible in precision welding. Its precision, adaptability, and portability make it a cornerstone of modern metalworking, providing professionals with the tools they need to create, repair, and innovate with confidence.