Rectangular Boxes vs Other Box Shapes: A Practical Comparison

Packaging shape plays a crucial role in how products are stored, transported, displayed, and perceived by customers. While packaging comes in many forms—cylindrical, pyramid, triangular, and custom die-cut shapes—rectangular boxes remain one of the most widely used options across industries. Their practicality, strength, and adaptability make them a preferred choice for both retail and logistics.

This article provides a detailed comparison between rectangular boxes and other packaging shapes, focusing on efficiency, protection, usability, and overall value.

Why Packaging Shape Matters in Modern Commerce

The shape of packaging impacts more than aesthetics. It affects:

-

Storage efficiency

-

Transportation costs

-

Product protection

-

Shelf presentation

-

Customer handling experience

Among all options, corrugated rectangular packaging is widely adopted because it aligns well with supply chain requirements while offering dependable performance.

Structural Efficiency and Space Utilization

Rectangular boxes excel in space management, especially when compared to round or irregular-shaped packaging.

Advantages of Rectangular Shapes

-

Stack neatly without wasted space

-

Fit easily on pallets and shelves

-

Allow uniform arrangement in warehouses

-

Reduce empty gaps during shipping

Other shapes, such as cylindrical or pyramid packaging, often leave unused spaces when stacked, increasing storage and transportation inefficiencies.

Comparison with Other Shapes

|

Shape Type |

Space Efficiency |

Stackability |

|

Rectangular |

High |

Excellent |

|

Cylindrical |

Low |

Poor |

|

Pyramid |

Very Low |

Limited |

|

Irregular |

Inconsistent |

Difficult |

For brands aiming to optimize logistics, rectangular designs remain the most practical choice.

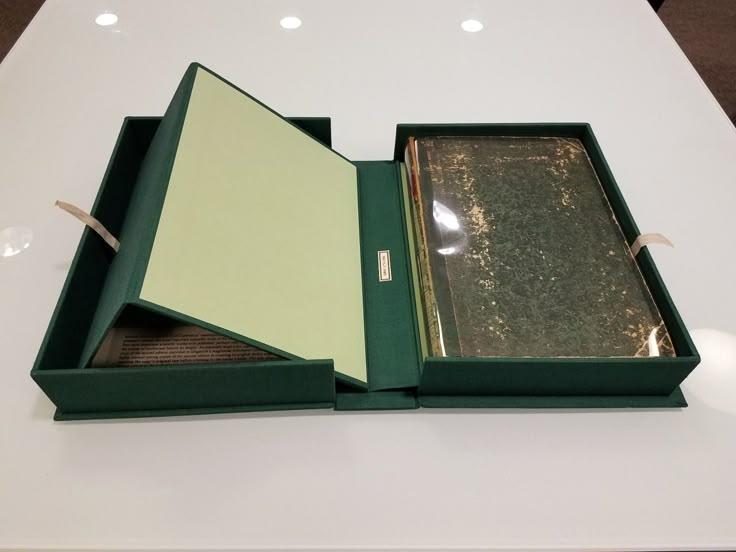

Product Protection and Durability

Packaging must safeguard products from damage during transit and storage. Rectangular boxes provide superior structural integrity due to evenly distributed pressure points.

Protective Benefits

-

Strong edges and flat surfaces absorb impact

-

Compatible with inserts, dividers, and cushioning

-

Ideal for packaging for fragile items such as glassware, electronics, and cosmetics

In contrast, curved or asymmetrical boxes can be harder to reinforce and may require additional materials to achieve the same level of protection.

Manufacturing and Cost Efficiency

Rectangular packaging is easier and more cost-effective to manufacture.

Why Rectangular Boxes Cost Less

-

Standardized die-lines

-

Minimal material waste

-

Faster production cycles

-

Lower tooling costs

Unconventional shapes often require complex tooling, increased labor, and higher production time, which drives up costs without necessarily improving functionality.

Versatility Across Industries

Rectangular boxes are widely used because they adapt easily to multiple industries and product categories.

Common Applications

-

Food and beverage packaging

-

Electronics and accessories

-

Apparel and footwear

-

Pharmaceuticals

-

Subscription boxes

They also perform exceptionally well in packaging for retail display, offering ample surface area for branding, product information, and visual appeal.

Branding and Design Flexibility

Flat panels make rectangular boxes ideal for printing and finishing techniques.

Design Advantages

-

Large printable surfaces

-

Clear logo visibility

-

Consistent branding placement

-

Support for embossing, foiling, and UV finishes

Other shapes often limit printable areas or distort graphics, reducing brand clarity on shelves.

Sustainability Considerations

Rectangular boxes are more eco-conscious when compared to complex packaging shapes.

Environmental Benefits

-

Efficient material usage

-

Easier recycling

-

Reduced shipping emissions due to compact stacking

-

Compatible with biodegradable and recycled materials

Brands aiming for sustainability often choose space-efficient packaging design to reduce their carbon footprint without compromising performance.

Consumer Convenience and Handling

From a customer perspective, rectangular boxes are easy to handle, open, and reuse.

User-Friendly Features

-

Simple opening mechanisms

-

Easy resealing options

-

Stackable for home storage

-

Reusable for secondary purposes

Odd-shaped packaging may attract attention initially, but often sacrifices convenience and usability.

Rectangular Boxes vs Aesthetic-Driven Shapes

While unique shapes can create novelty, they are best suited for limited-edition or promotional products rather than everyday packaging.

When Other Shapes Make Sense

-

Luxury gifting

-

Seasonal promotions

-

Display-only packaging

However, for long-term scalability and operational efficiency, rectangular packaging remains unmatched.

Cost vs Value Analysis

Rectangular boxes offer a strong balance between cost, performance, and visual appeal.

Key Value Factors

-

Lower shipping costs

-

Reduced material waste

-

Strong product protection

-

Reliable branding surface

These advantages make them suitable for brands seeking dependable customized product packaging that supports growth and consistency.

Future Trends in Rectangular Packaging

Modern innovations continue to enhance rectangular packaging designs.

Emerging Developments

-

Smart packaging integration

-

Sustainable coatings

-

Modular inserts

-

Minimalist branding aesthetics

Brands increasingly invest in customized product packaging that blends functionality with visual appeal while keeping operational efficiency intact.

Final Thoughts

When comparing rectangular boxes with other packaging shapes, the advantages are clear. Rectangular packaging delivers superior space utilization, structural strength, cost efficiency, and branding flexibility. While alternative shapes may offer novelty, they often fall short in scalability and logistics.

For businesses focused on protection, sustainability, and operational practicality, rectangular boxes remain the most reliable packaging solution in today’s competitive market.