Industrial Simulation Training Solutions Market Trends by Market Research Future

As Per Market Research Future, Industrial Simulation Training Solutions are gaining traction as effective tools for training operators in complex industrial environments. These solutions provide realistic simulations that replicate real-world scenarios, allowing trainees to practice and refine their skills safely. The growing emphasis on operational efficiency and safety in industries such as manufacturing and energy is driving the demand for industrial simulation training solutions. As companies prioritize effective training methodologies, this segment is projected to experience substantial growth in the coming years.

The operator training simulator market has emerged as a critical component of modern industrial development, supporting organizations in preparing skilled operators for complex processes and high-risk environments. As industries such as oil and gas, power generation, chemicals, mining, and manufacturing adopt advanced automation and digital systems, the need for effective and realistic training solutions has intensified. Operator training simulators replicate real-world operational scenarios, enabling trainees to gain hands-on experience without exposing facilities or personnel to operational risks.

Evolution of Simulation-Based Training

Simulation-based training has evolved significantly over the past few decades, transitioning from basic computer-based models to sophisticated virtual environments that mirror real plant operations. Early simulators focused on individual equipment behavior, while modern operator training simulators integrate entire process flows, control systems, and emergency scenarios. This evolution reflects the growing complexity of industrial operations and the increasing emphasis on safety, efficiency, and regulatory compliance.

Key Market Drivers and Growth Factors

Several factors are driving growth in the operator training simulator market. One of the most influential drivers is the rising focus on workplace safety and accident prevention. Industries with hazardous operations increasingly rely on simulators to train operators to respond effectively to abnormal situations. Additionally, the shortage of skilled labor across industrial sectors has pushed companies to invest in structured training programs that accelerate operator competency. Digital transformation initiatives and the integration of advanced process control systems further support the adoption of simulator-based training solutions.

Role of Digitalization and Industry 4.0

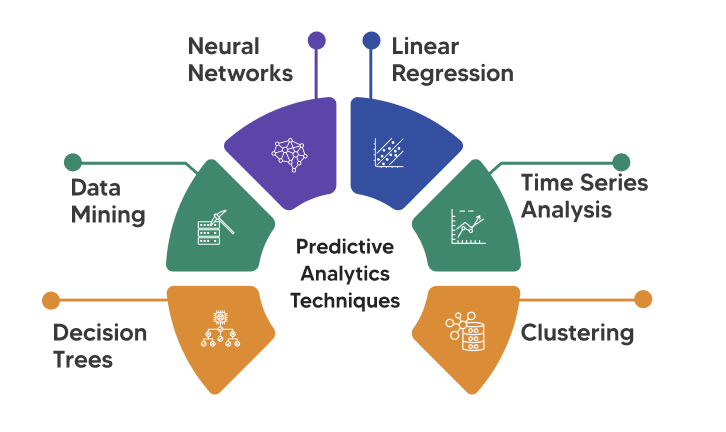

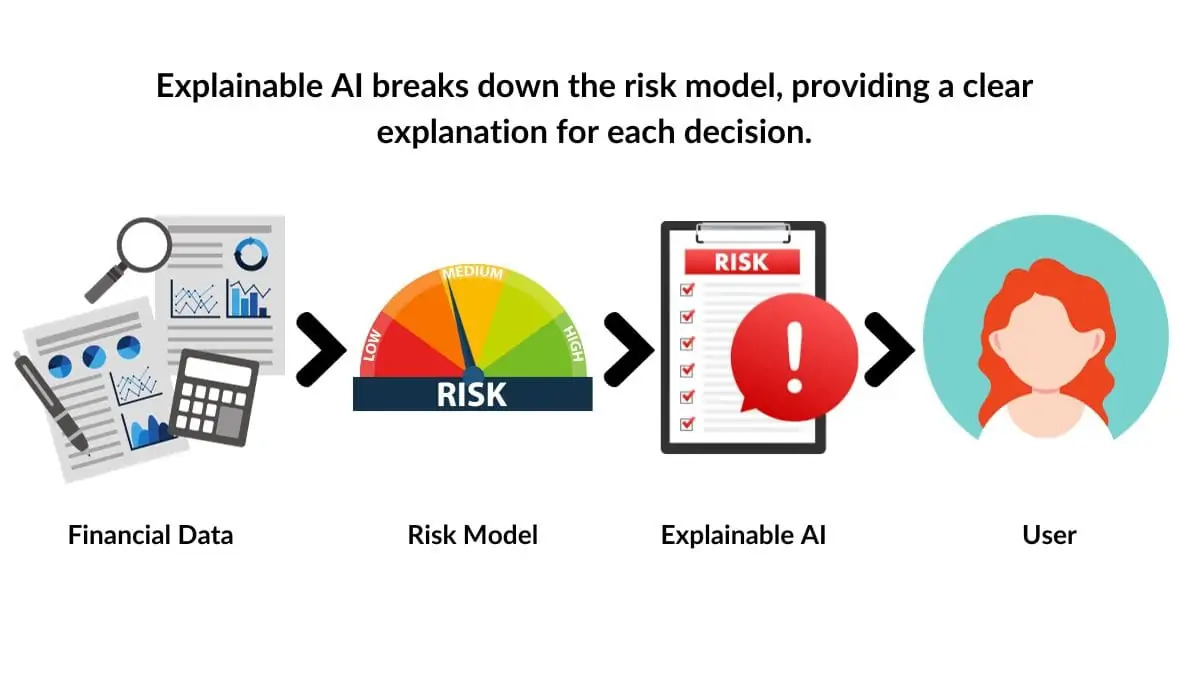

Digitalization and Industry 4.0 trends are reshaping the operator training simulator market. Advanced analytics, artificial intelligence, and digital twins are being embedded into simulation platforms to provide more realistic and adaptive training experiences. These technologies allow training programs to be customized based on operator performance, improving learning outcomes. As smart factories and connected plants become more prevalent, operator training simulators play a vital role in aligning workforce capabilities with advanced industrial systems.

Application Across End-Use Industries

The operator training simulator market serves a wide range of industries, including oil and gas, power generation, chemicals, pharmaceuticals, metals, and water treatment. In the oil and gas sector, simulators are used to train operators in drilling, refining, and pipeline operations. Power plants rely on simulators to ensure stable plant operation and emergency preparedness. Chemical and pharmaceutical manufacturers utilize training simulators to maintain process consistency and compliance with stringent regulations.

Benefits of Operator Training Simulators

Operator training simulators offer numerous benefits, including improved operational efficiency, reduced downtime, and enhanced safety performance. By allowing operators to practice complex procedures in a virtual environment, organizations can minimize errors during actual operations. Simulators also support continuous learning, enabling experienced operators to refine their skills and adapt to new technologies or process changes. These benefits contribute to long-term cost savings and improved operational resilience.

Regional Market Outlook

The operator training simulator market demonstrates strong growth potential across both developed and emerging regions. Developed economies continue to invest in advanced training technologies to modernize aging industrial infrastructure. Meanwhile, emerging markets are adopting operator training simulators as part of industrial expansion and capacity-building initiatives. Government support for industrial safety standards and workforce development further strengthens regional market growth.

Competitive Landscape and Innovation Trends

Competition in the operator training simulator market is driven by innovation, customization capabilities, and integration with existing control systems. Market participants focus on developing flexible platforms that can be adapted to different industries and operational requirements. The increasing use of cloud-based simulation, virtual reality, and augmented reality is expected to create new opportunities for market expansion.

Future Outlook of the Operator Training Simulator Market

The future of the operator training simulator market is shaped by ongoing industrial automation, increasing safety regulations, and the need for skilled operators. As industries continue to embrace digital technologies, training simulators will become more intelligent, immersive, and data-driven. These advancements will further position operator training simulators as essential tools for sustainable industrial growth.

Frequently Asked Questions

What is an operator training simulator used for

An operator training simulator is used to train industrial operators by replicating real-world process operations and emergency scenarios in a virtual environment.

Which industries benefit most from operator training simulators

Industries such as oil and gas, power generation, chemicals, pharmaceuticals, and manufacturing benefit significantly due to complex and safety-critical operations.

How do operator training simulators improve safety

They allow operators to practice handling abnormal and emergency situations without real-world risks, reducing the likelihood of accidents.

More Trending Reports Industrial Automation Equipment Market Report by Market Research Future